Building the Future of Manufacturing

About us

Samuel Automation specializes in seamlessly integrating modern automation solutions into existing manufacturing environments or developing systems for new production needs. We excel at partnering with our manufacturing customers to create optimal ROI for their operations. Our in-house vision engineering supports those projects that are more complex. Our experts and experience ensure production-worthy solutions.

Our services

Vision Inspection Service

We utilize proprietary intelligence software, industry-leading vision systems and process monitoring technology to mitigate risks in real time, improving quality, compliance and time to market for your medical devices.

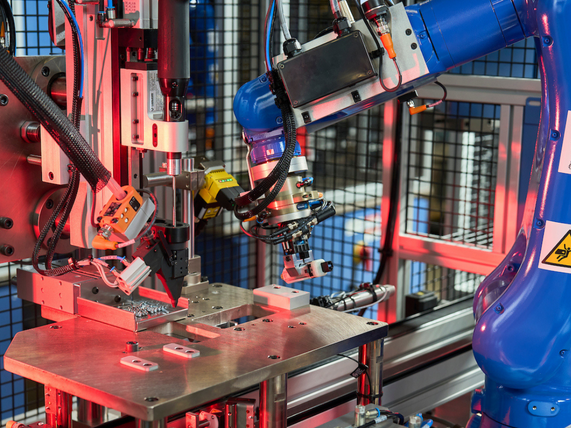

Complex Part Assembly

As experts in solving complex problems, we partner with OEMs to design and build automated assembly systems, with capabilities ranging from loading and transfers, to testing, inspecting, packing and unloading.

Autonomous Mobile Robots

Our Autonomous Mobile Robots (AMR) are transforming industrial workflows by introducing unmatched efficiency, safety, and flexibility to operations.

Samuel Automation comprises the combined expertise of multiple automation industry leaders, each excelling in diverse capabilities developed over decades.

Engineering excellence across industries & solutions

CAPABILITIES

Our team applies broad expertise to exceed expectations. With advanced skills and experience, we tackle challenges with precision to deliver dependable automation solutions.

Industries

We solve complex manufacturing challenges through custom automation—designing and integrating turnkey systems that unite proven technology with precision engineering.

Partner Services

We solve complex manufacturing challenges through custom automation—designing and integrating turnkey systems that unite proven technology with precision engineering.

Implementation

Contact us